Source: Los Angeles Tines –latimes.com

Source: Los Angeles Tines –latimes.com

By Samantha Masunaga

The secretive Skunk Works in Palmdale has over the years spawned such sleek aircraft as the SR-71 Blackbird spy plane and the F-117 Nighthawk stealth fighter.

Today, one of the facility’s hangars houses a 120-foot-long, 21-foot-tall dirigible that resembles a cloud with three puffs — the prototype of a much larger Hybrid Airship that Lockheed Martin Corp. has touted as a way to deliver heavy cargo and personnel to remote locations.

Reporters are shown the P-791 Hybrid Airship prototype on Wednesday at Lockheed Martin’s Skunk Works facility in Palmdale.

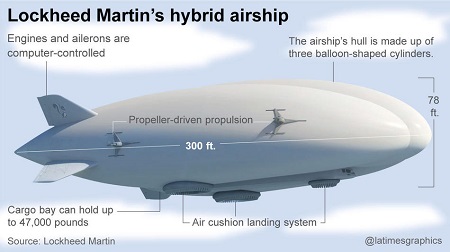

Photo: Al Seib/Los Angeles TimesWhen fully built, the LMH-1 will be a 21 metric ton, 300-foot-long and 80-foot-tall airship that is intended to carry truck-sized loads to areas that are inaccessible to trucks and other more traditional modes of transportation.

It could potentially be used in the oil and gas or mining industries, as well as for humanitarian relief, said Grant Cool, chief operating officer of Atlanta-based Hybrid Enterprises LLC, the exclusive reseller of the Lockheed Martin Hybrid Airship.

Lockheed Martin officials couldn’t confirm whether they had any orders yet, but said there were more than a dozen interested parties.

“We are targeting a market that is not really competing with anything else out there,” Cool said. “We are looking for opportunities that don’t really exist right now.”

The LMH-1, which has yet to be built, could have its first flight by late 2017, and is expected to be in commercial service by the end of 2018. A single airship will cost $40 million.

Grant Cool, left, chief operating officer of Hybrid Enterprises, shows the passenger compartment configuration of the Lockheed Martin Hybrid Airship on Wednesday.

Photo: Al Seib/Los Angeles Times.Lockheed Martin has said the airship will be able to carry up to 47,000 pounds and burn less fuel than conventional aircraft.

The airship will have four fairly small engines and gets about 80% of its lift from helium. An air-cushion landing system, which resembles three round kiddie pools, allows the airship to land on wild terrain such as open water, sand, snow or ice. The air-cushion landing system also allows the dirigible to stick to the ground like a suction cup so that it doesn’t move with the wind, said Bob Boyd, program manager for the Lockheed Martin hybrid airships.

In a mock-up of the LMH-1’s 150-foot gondola, which includes the cockpit and cargo bay, 19 passengers sit in rows of two or three immediately behind two pilot chairs. Lockheed Martin officials said they also plan to have Wi-Fi onboard.

Despite the passenger comforts, Craig Johnston, business director for Lockheed Martin’s Skunk Works facility, emphasized the airship’s focus on cargo. A square-shaped cargo bay in the back of the cockpit was specifically designed with loading in mind.

“This is designed from the ground up to be a cargo vehicle,” he said.

And it won’t be the only one. Boyd said there are plans to make a medium-size 90-ton hybrid airship in two to three years that could compete with trucking and rail vehicles in remote areas, and eventually an 800-foot-long airship weighing 500 tons. He said the market “is interested” in the smaller 21-metric-ton airship, but interest increases as the dirigible gets larger and costs get cheaper.

The hybrid airship program is expected to employ about 150 workers in Palmdale, though Johnston said the positions might not necessarily be new jobs.

The airship is the result of more than 20 years’ worth of research. In 2006, the company flew the P-791, the one-third size prototype currently in the Skunk Works hangar, over its facilities in Palmdale and completed all of its in-flight test objectives.

The biggest challenge for Lockheed Martin and Hybrid Enterprises is changing customers’ ideas about transportation, Boyd said.

“It’s just the acceptance of a new way of doing things,” he said. “It’s more from a business perspective than a technology perspective. We think it will be a rapidly accepted market.”

The airship will have four fairly small engines and gets about 80% of its lift from helium. An air-cushion landing system, which resembles three round kiddie pools, allows the airship to land on wild terrain such as open water, sand, snow or ice. The air-cushion landing system also allows the dirigible to stick to the ground like a suction cup so that it doesn’t move with the wind, said Bob Boyd, program manager for the Lockheed Martin hybrid airships.

In a mock-up of the LMH-1’s 150-foot gondola, which includes the cockpit and cargo bay, 19 passengers sit in rows of two or three immediately behind two pilot chairs. Lockheed Martin officials said they also plan to have Wi-Fi onboard.

Despite the passenger comforts, Craig Johnston, business director for Lockheed Martin’s Skunk Works facility, emphasized the airship’s focus on cargo. A square-shaped cargo bay in the back of the cockpit was specifically designed with loading in mind.

“This is designed from the ground up to be a cargo vehicle,” he said.

And it won’t be the only one. Boyd said there are plans to make a medium-size 90-ton hybrid airship in two to three years that could compete with trucking and rail vehicles in remote areas, and eventually an 800-foot-long airship weighing 500 tons. He said the market “is interested” in the smaller 21-metric-ton airship, but interest increases as the dirigible gets larger and costs get cheaper.

The hybrid airship program is expected to employ about 150 workers in Palmdale, though Johnston said the positions might not necessarily be new jobs.

The airship is the result of more than 20 years’ worth of research. In 2006, the company flew the P-791, the one-third size prototype currently in the Skunk Works hangar, over its facilities in Palmdale and completed all of its in-flight test objectives.

The biggest challenge for Lockheed Martin and Hybrid Enterprises is changing customers’ ideas about transportation, Boyd said.

“It’s just the acceptance of a new way of doing things,” he said. “It’s more from a business perspective than a technology perspective. We think it will be a rapidly accepted market.”

Source: Los Angeles Tines –latimes.com