By: Antony Funnell

Across the world teams of engineers are working to try and resurrect the airship, arguing their heavy-lifting ability makes them an energy efficient alternative to cargo planes and helicopters. Some claim airships could even allow factories to set up in remote communities, without the need for roads or airports.

It looks more like a bouncy castle than a futuristic means of transport, but the solar ship is in fact a state-of-the-art flying machine.

Its blimp-like appearance belies a very serious mission: to carry medicines and medical equipment to those who live in the world’s most inaccessible terrains.

In late 2011 the first prototype solar ship successfully launched from a cold Canadian runway, fulfilling a thirty year dream for Canadian entrepreneur Jay Godsall.

‘It’s been a very slow development,’ he says. ‘I think we’re close technically.’

It’s hard to define exactly what the solar ship is. Wired magazine has called it a ‘mash-up’ between a light plane and a ‘blimp’. Mr. Godsall says the design harks back to the ‘great bush plane tradition of Canada, Australia and Africa.’ Its large inflatable wing, shaped like an arrow head, is filled with helium, but the gondola attached beneath looks and functions like an aeroplane.

‘We get about 30 per cent of our lift from helium and 70 per cent from the aerodynamics of the wing,’ Mr. Godsall says.

However you describe it, the solar ship, which gets its name from the array of solar panels covering the top surface of its wing, is just one example of a range of new hybrid craft currently being developed using the design of a distant past.

For most of us, the airship remains an iconic symbol of the 1920s and 30s. It speaks of an age of slow-moving luxury travel and of spectacular disasters. The Hindenburg, Britain’s R101, America’s Shenandoah—each met a fiery end. But as increasing fuel costs and logistical difficulties bite into the global aviation industry, the zeppelin is now being revisited.

The airship is back, but it’s being reinvented for the modern age.

It could be argued that what doomed the first zeppelin era was a form of nationalistic penis envy. In the inter-war years the great nations of the world competed with each other to build the biggest possible craft, to try and outdo each other in size. But the bigger they got, the more vulnerable their airships became.

The R101 was the best example of this. It was commissioned by Ramsay MacDonald’s government in the late 1920s as the flagship of an Imperial Airship Scheme, a grand vision to link the far flung reaches of the world’s largest empire. After initial trials, an eleventh hour decision was made to lengthen the dirigible’s rigid frame by 14 meters in preparation for its maiden voyage to India, timed to coincide with the 1930 Imperial Conference in London. The extension made the R101 the longest airship in the world, but it also reduced the strength of its metal frame. As a consequence, it only got as far as rural France before plunging to earth during a severe storm.

Perhaps more importantly, during the first part of the 20th century there was also a failure to define a lasting and meaningful function for the airship. In World War I, German zeppelins were used as long-range bombers, but they soon lost that role to aircraft. Then, during the 20s and 30s, manufacturers desperately tried to find a place for the airship as a long-distance passenger craft, but speed and reliability once again got the better of them.

But unlike the early incarnations of the zeppelin, most modern airships are being designed with an emphasis on cargo transportation. Dr Bob Boyd from the aeronautics firm Lockheed Martin envisages the airship as the ‘pick-up truck of the sky’.

‘It’s really there to haul things from place to place. To do it every day and just do it reliably. There are a lot of things that don’t necessarily need to go at 500 miles an hour.’

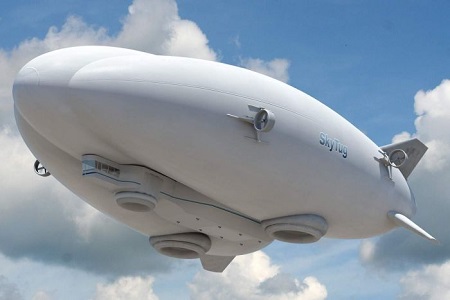

Lockheed Martin’s engineers have already tested a prototype and are busy developing three different sized craft. The smallest, expected to have a range of 1000 km and a payload of 20 tons, is to be called the ‘Sky Tug’. And the largest, the ‘Sky Liner’, is anticipated to have a lift capacity of 500 tons.

Dr Boyd says two factors have motivated his firm to invest in airships. Firstly, the rising cost of fuel, and secondly, the ability of the airship to land on a dime, opening up new markets that otherwise are locked out of global trade by their lack of infrastructure.

‘If you look at the globe, not even half of it is covered with decent infrastructure,’ he says. ‘[T]he airships enable you to quickly establish your manufacturing centers far from normal infrastructure and still be able to create commerce. And then of course eventually you would build in roads and rail, et cetera. But initially it enables you to start that.’

Like Jay Godsall’s solar ship, the sky tug prototype developed by Lockheed Martin takes the airship and radically redesigns its traditional form.

Lockheed Martin’s concept design for the Sky Tug, capable of carrying a 20 tonne payload

Photo: Lockheed MartinIn profile, the craft maintains the familiar cigar shape of its zeppelin forebears, but viewed from above or below, there are significant differences. It’s as though the airship’s body has been flattened out. ‘These aren’t like the zeppelins of old with the rigid structure; they’re non-rigid,’ says Dr Boyd. ‘The cross-sections are all circles, but in our case, it is a trilobe, if you will. It’s actually more like a two-and-a-half lobe, where we take two-and-a-half circles and sort of interpose them over the top of each other. If you take three Olympic rings and imagine them together, that’s really what the shape looks like in cross-section.’

Crucially the sky tug also utilizes a combination of different forms of power to gain altitude and to propel itself. ‘It’s not just a buoyant airship,’ says Dr Boyd, ‘It actually mixes three forms of lift: there’s the buoyant lift from the gas, from the helium; there is aerodynamic lift from the actual airfoil shape—it’s actually a wing, the shape of the body, that generates aerodynamic lift; and then we can also vector the engines up and down and generate direct lift from the engine power. So we use all three forms of lift and that’s what gives us a very high degree of efficiency and at the same time a fairly high degree of flexibility in order to be able to get to these places and unload and load lots of cargo.’

Among Lockheed Martin’s major competitors is the California-based company Aeros. Their prototype dirigible, christened the Aeroscraft, also has a flattened body, but with its silver-grey skin and side fins it looks something like a bloated metallic whale. Two of the company’s partners are DARPA—the United States’ premier defense research funding arm—and also NASA.

‘I think that they could play a huge role in air cargo,’ says Dr Alan Weston, the Director of Programs and Projects at the NASA Ames Research Center. ‘New airship technologies have the promise to reduce the cost of moving things per ton-mile by up to an order of magnitude. If you could deploy airships that have vertical take-off and landing capability, like the ones we’re working on right now, they can actually be quicker for cargo transportation than the use of aeroplanes today. I can see them making a huge contribution in the decades to come: a larger airship, a class of vehicle that can lift up to 500 tons, that could be actually more fuel efficient than even a truck.’

NASA’s interest in airship technology, according to Dr Weston, centers around its mission to explore what he calls ‘green aviation’ also known as ‘environmentally responsible aviation’, as a way of cutting back on the carbon footprint of air travel.

But while there’s healthy competition in the modern airship industry, there are still many difficulties yet to overcome. One of the major problems faced by airships isn’t haulage capacity, but buoyancy management. When you’re talking about payloads of several hundred tons, problems with buoyancy control during loading and unloading could be catastrophic.

To get around the problem, the Aeroscraft’s engineers have devised a system which operates like a set of human lungs. As Dr Weston explains, ‘The project uses compression of helium to control buoyancy. When the vehicle is on the ground, without this buoyancy control as soon as we start taking things off, the vehicle would want to fly away. The helium in the main envelope is taken and stored in bags inside the airship at a slightly higher pressure. As you do that, air is taken in from the outside into lungs that are attached on the side of the vehicle. So the analogy of breathing is a good one. And the overall lift of the vehicle is equal to the weight of the air that is being displaced by the helium. And as you change that, you can control the amount of buoyancy that the vehicle has.’

‘This turns out to be a critical factor in the operability of these new airships,’ he says. ‘[I]t means that you can on-load and offload payloads up to 500 tons without using ballast. And, as you can imagine, when you start thinking about very large payloads, moving 500 tons of ballast on and off an airship becomes very difficult.’

Key also to the further development of modern airship technology is a lack of readily available capital. In November 2012, a sudden rise in the cost of helium was cited as the major reason for the collapse of the Californian zeppelin company Airship Ventures. And even the mega aeronautics players like Lockheed Martin and Aeros face an ongoing struggle to secure investors.

Dr Boyd says the aviation business can be extremely ‘conservative’ about investing in new developments, and overcoming investor reticence about new technologies is a significant issue. There’s also the ongoing difficulty of holding on to investors, as another of Lockheed Martin’s competitors discovered earlier this year.

In 2010, Northrop Grumman had beaten its rival to a half-a-billion-dollar development contract with the US Army. The contract was focused on exploring the potential of airship technology not just for cargo haulage, but for battlefield surveillance.

With US Military’s backing, Northrop Grumman successfully developed and trialed an airship called the LEMV—short for Long Endurance Multi-Intelligence Vehicle. And after a successful test flight in August 2012, spokesman Tim Paynter proudly told Future Tense: ‘Over the next couple of years we will certainly see a lot more activity on this program.’

But it was not to be. In March this year the US Military announced the surprise cancellation of the contract.

‘I suspect that the sort of reasons involved there are just not meeting performance specifications,’ says senior aviation analyst Peter Harbison from the Centre for Aviation. ‘These aircraft are potentially useful, particularly on difficult terrain and things like that. But, of course, if you’re using them in areas where there is some competition for the skies, or where there is a threat of military attack, these are very, very vulnerable pieces of equipment.’

The cancellation of the LEMV project was a serious embarrassment for Northrop Grumman, but according to Peter Harbison, it was also bad news for the industry as a whole, because all of the major commercial aircraft manufacturers derive the vast bulk of their revenue from military contracts, not from civil aircraft. ‘The civil side of the business, which is the one we hear about, is much, much smaller than the military side,’ he says. ‘So in this case, if you’ve got the defence forces not prepared to back production, then the cost of production for a civil operation becomes that much harder.’

Despite the grounding of the LEMV, both Lockheed Martin and Aeros are pushing forward with their airship development plans. Both say they foresee having a marketable product within a few years.

Meanwhile, in Burundi, Jay Godsall is engaged in securing the relationships that will eventually allow his far more modestly-funded hybrid airship to begin operations. After a relatively unsuccessful attempt to crowd-source development funding online, Mr Godsall’s company the Solar Ship Foundation secured a $US 2.1 million assistance grant from the Canadian government in February this year.

He says he’s confident that after 30 years of planning, building and testing, 2014 will be the year the solar ship takes off. And despite the technical and financial difficulties his company has experienced over time, he believes his hybrid airship will succeed, because it can help developing countries address a significant and pressing problem; and because it meets an existing gap in the global transport market.

‘I grew up with engineers and I grew up with inventors. I’m not an engineer and inventor myself. I come from the demand side of the equation, so I come from the headache side of the equation,’ says Jay Godsall. ‘If you look at the Democratic Republic of Congo, you have 26 paved airports and only 2794 km of paved road. So you have a massive place—2.5 million km2—and virtually no transport infrastructure. But they’ve got 70 million people, almost 75 million people, so that becomes the type of place where transport economics are extremely costly. And of course medical supplies for them, very important, because when rainy season kicks in that’s one of the things that does not get in and out. So that’s the historical context.’

Source: abc.net.au